Automatic relays are integral components in modern electrical systems, serving as the unsung heroes that ensure efficient operation, safety, and reliability. These devices function as automatic switches, monitoring electrical parameters and responding to changes by opening or closing circuits without human intervention. Their importance spans across residential, commercial, and industrial applications, making them indispensable in today's technologically advanced world.

At its core, an automatic relay is designed to detect abnormal conditions such as overcurrent, overvoltage, undervoltage, or phase imbalance. When these conditions exceed predefined thresholds, the relay activates, interrupting the circuit to prevent damage to equipment or potential hazards like fires or electrical shocks. For example, in a home's electrical panel, an automatic relay may detect a short circuit and immediately cut power to the affected circuit, safeguarding appliances and preventing electrical fires. Similarly, in industrial settings, relays protect expensive machinery from damage caused by voltage fluctuations or overloads, minimizing downtime and maintenance costs.

The working principle of an automatic relay involves three main components: the sensing element, the control circuit, and the switching mechanism. The sensing element continuously monitors electrical parameters such as current, voltage, or temperature. When a parameter deviates from the normal range, the control circuit processes this information and triggers the switching mechanism. This mechanism, typically an electromagnet or solid-state switch, opens or closes the circuit to restore normal operation or isolate the faulty section. The speed and accuracy of this process are critical, as even a slight delay can lead to significant damage.

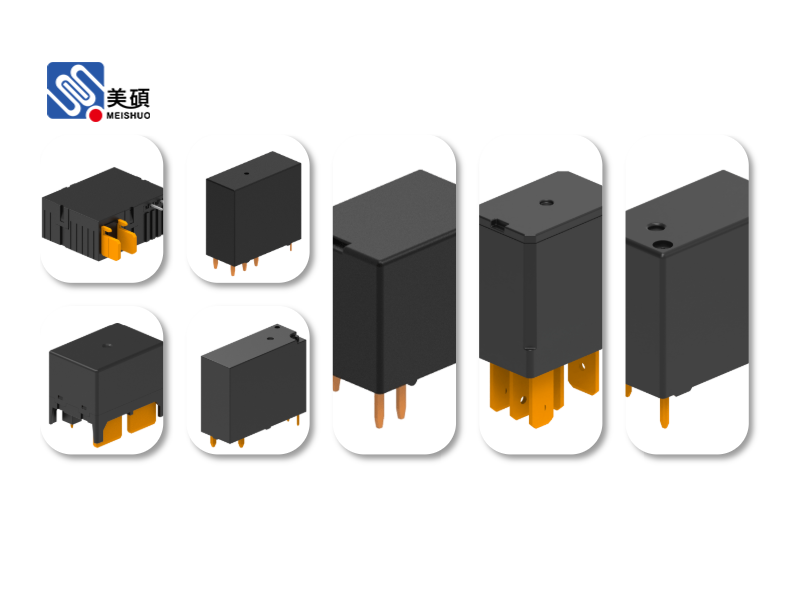

Advancements in technology have led to the development of various types of automatic relays, each tailored to specific applications. Electromechanical relays, the traditional type, use an electromagnet to actuate mechanical contacts. They are known for their durability and reliability but may have slower response times compared to solid-state relays. Solid-state relays, on the other hand, use semiconductor devices like transistors or thyristors to switch circuits. They offer faster response times, higher precision, and longer lifespans, making them ideal for applications requiring rapid switching or high-frequency operations.

Another important category is the protective relay, which is widely used in power systems to protect transformers, generators, and transmission lines. These relays are equipped with advanced algorithms and communication capabilities, allowing them to coordinate with other relays in the system. For instance, in a power grid, a protective relay may detect a fault in a transmission line and send a signal to adjacent relays to isolate the fault, ensuring that the rest of the grid remains operational. This coordination is essential for maintaining grid stability and minimizing power outages.

In addition to protection, automatic relays also play a crucial role in automation and control systems. They enable the remote operation of electrical devices, allowing for centralized monitoring and management. For example, in a smart building, relays control lighting, heating, ventilation, and air conditioning (HVAC) systems based on occupancy or environmental conditions. This not only enhances energy efficiency but also improves comfort and convenience for occupants.

The integration of automatic relays with digital technology has further expanded their capabilities. Modern relays are often equipped with microprocessors and communication interfaces, enabling them to collect and transmit data in real-time. This data can be analyzed to predict potential failures, optimize performance, and schedule maintenance proactively. For instance, in a manufacturing plant, a relay may monitor the current draw of a motor and alert maintenance personnel when it exceeds normal levels, indicating a potential bearing failure. This predictive maintenance approach reduces unplanned downtime and extends the lifespan of equipment.

Despite their numerous benefits, automatic relays require proper installation and maintenance to ensure optimal performance. Incorrect wiring or calibration can lead to false trips or failure to actuate when needed. Regular inspections, testing, and replacement of worn components are essential to maintain reliability. Additionally, as technology evolves, it is important to update relays to meet changing standards and requirements, ensuring compatibility with new equipment and systems.

In conclusion, automatic relays are vital components in modern electrical systems, providing protection, automation, and control. Their ability to detect and respond to abnormal conditions quickly and accurately makes them indispensable for ensuring safety, efficiency, and reliability. As technology continues to advance, the role of automatic relays will only grow, with new features and capabilities enhancing their performance and expanding their applications. Whether in a home, office, or industrial facility, automatic relays work tirelessly behind the scenes to keep our electrical systems running smoothly, making them an essential part of our daily lives.