Relay circuits are fundamental components in modern electrical and electronic systems, serving as essential interfaces between low-power control signals and high-power loads. These versatile devices have been integral to technology for over a century, evolving from electromechanical switches to sophisticated solid-state components while maintaining their core function: to control one electrical circuit using another. This article explores the principles behind relay circuits, their diverse applications across industries, and key design considerations for engineers and technicians.

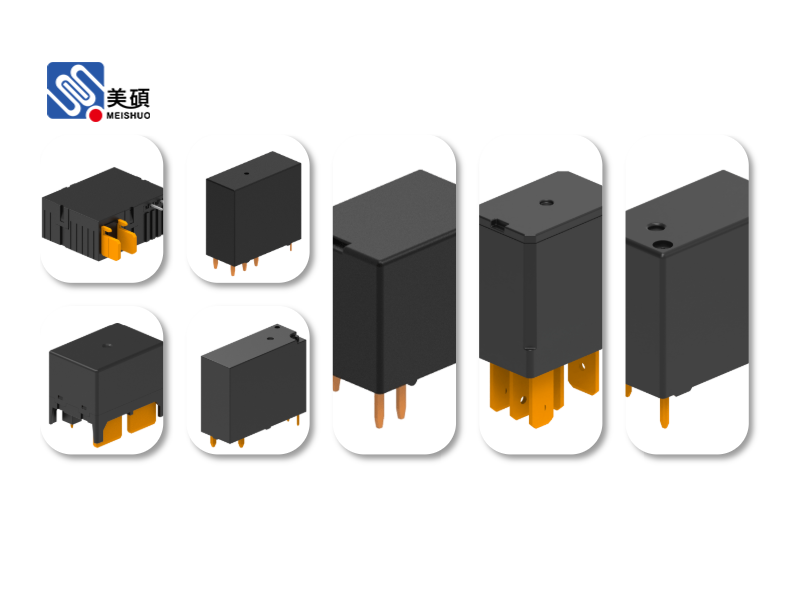

At its most basic level, a relay circuit consists of two primary parts: the control circuit and the load circuit. The control circuit contains an electromagnet that, when energized by a small current, generates a magnetic field. This field attracts a movable armature connected to a set of contacts, causing them to switch positions and complete or interrupt the load circuit. The beauty of this design lies in its ability to isolate the control and load circuits, providing both electrical separation and voltage/current transformation capabilities. Early relays used electromagnetic coils with iron cores and mechanical contacts, but modern versions include solid-state relays (SSRs) that replace moving parts with semiconductor devices for faster switching and longer lifespans.

The applications of relay circuits span virtually every industry, from automotive systems to industrial automation and consumer electronics. In automotive engineering, relays control critical functions like starter motors, headlights, and power windows, allowing low-current signals from the vehicle's computer to activate high-power components safely. Industrial control systems rely on relays for motor control, process automation, and safety interlocks, where they enable precise timing and sequential operations. Even in household appliances, relays manage compressor motors in refrigerators, heating elements in ovens, and pump systems in washing machines, ensuring efficient power distribution and user safety.

Designing effective relay circuits requires careful consideration of several key parameters. The voltage and current ratings of both the control and load circuits must match the relay's specifications to prevent damage or failure. Contact materials play a crucial role in performance; silver-nickel contacts offer excellent conductivity and corrosion resistance, while gold-plated contacts are ideal for low-current applications where reliability is paramount. Engineers must also account for coil resistance, operating temperature ranges, and switching speed requirements when selecting a relay for a specific task. For high-frequency applications, solid-state relays provide faster response times and eliminate mechanical wear, though they may generate more heat than their electromechanical counterparts.

Recent advancements in relay technology have expanded their capabilities beyond simple on/off control. Latching relays retain their state even after the control current is removed, useful for applications requiring memory functions. Time-delay relays introduce adjustable delays between input activation and output response, critical for sequential processes in manufacturing lines. Protective relays monitor electrical parameters like voltage, current, and frequency to detect faults and isolate problematic circuits, preventing equipment damage and ensuring system safety. These specialized relays demonstrate the adaptability of relay circuits to meet evolving technological demands.

Despite their widespread use, relay circuits present unique challenges that designers must address. Electromechanical relays produce audible clicks and mechanical wear, limiting their lifespan in high-cycle applications. Solid-state relays, while durable, generate heat during operation and may require heat sinks for high-power loads. Both types require careful attention to insulation and isolation to prevent electrical interference and ensure compliance with safety standards. Engineers must also consider environmental factors like temperature extremes, vibration, and humidity, which can affect relay performance and reliability.

In conclusion, relay circuits remain indispensable components in modern technology, bridging the gap between control systems and power applications. Their ability to provide electrical isolation, voltage transformation, and signal amplification makes them versatile tools across industries. As technology continues to advance, relay circuits will likely evolve further, incorporating digital intelligence and wireless capabilities while preserving their core function. Understanding the principles, applications, and design considerations of relay circuits is essential for anyone working with electrical systems, whether designing a simple household appliance or a complex industrial automation setup. By mastering these fundamentals, engineers can harness the full potential of relay circuits to create efficient, reliable, and safe electrical solutions for the challenges of tomorrow.