1, the installation direction If the direction of installation and the impact resistance of the relay in the same direction, give full play to the performance of the relay. It is suggested that the direction of impact be perpendicular to the direction of movement of the contact and the armature, which can effectively improve the vibration and shock resistance of the normally-closed contact under non-excitation conditions. Installation, the relay contact with the ground parallel to the ground, to avoid contact splatter, charcoal fell on the contact surface, improve contact reliability. Multiple sets of relays should be protected from light load contacts under large load contacts.

2, close-up installation Close installation of multiple relays, it will lead to abnormal fever, the general recommended 2mm spacing. Closely installed with a polarity or magnetic retention relay will affect the operating voltage.

3, the shell mounting relay, can not remove the shell first installed, in order to prevent loosening, damage, deformation, please use the spring washers. Tightening torque in the range of 0.5 ~ 70N · m.

4, plug-in relay insertion strength recommended for 40 ~ 70N.

5, to meet the same load requirements of products with different dimensions, according to the allowable installation space, the choice of low-height or small installation area of the product.

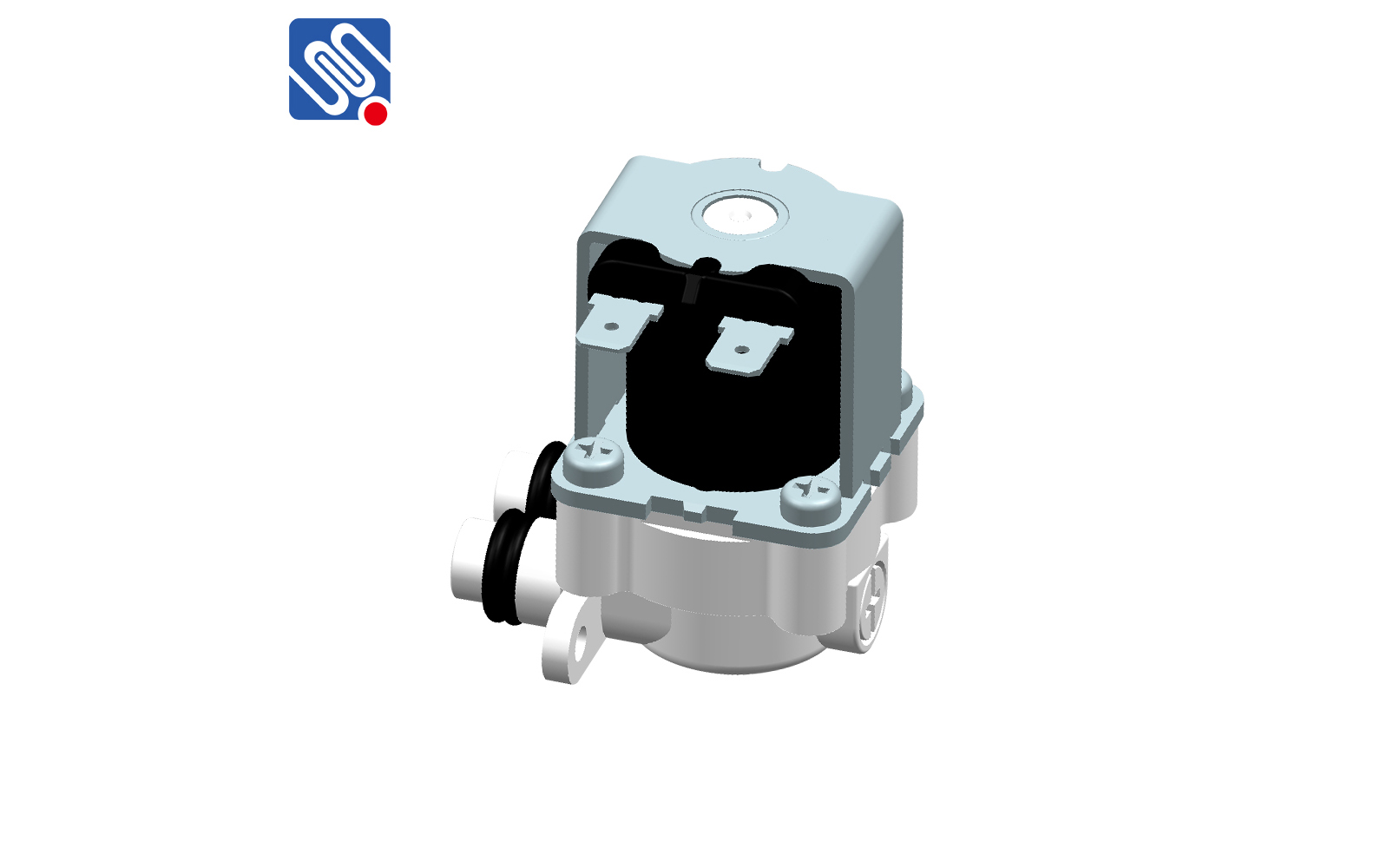

6, the installation of automotive relays are PCB board, ISO socket-mounted, ISO 280 socket-mounted and shell fixed, card installation. On the small size, not often replace the relay, the general use of PCB board, often replace the relay, the choice of socket installation. On the main loop current exceeds 20A relays, the general choice of socket fast connection, to prevent large current through the circuit board, resulting in circuit board heating damage (short-term work relay excluded). Large relays, the choice of shell-mounted, to prevent the impact, vibration conditions, the mounting foot damage.

selena

selena  Sales@msrelay.com

Sales@msrelay.com 13968707033

13968707033

+86-577-62518811

+86-577-62518811