stainless steel and plastic solenoid valves: choosing the right material for your needs

Release time:2025-03-14 01:23:02

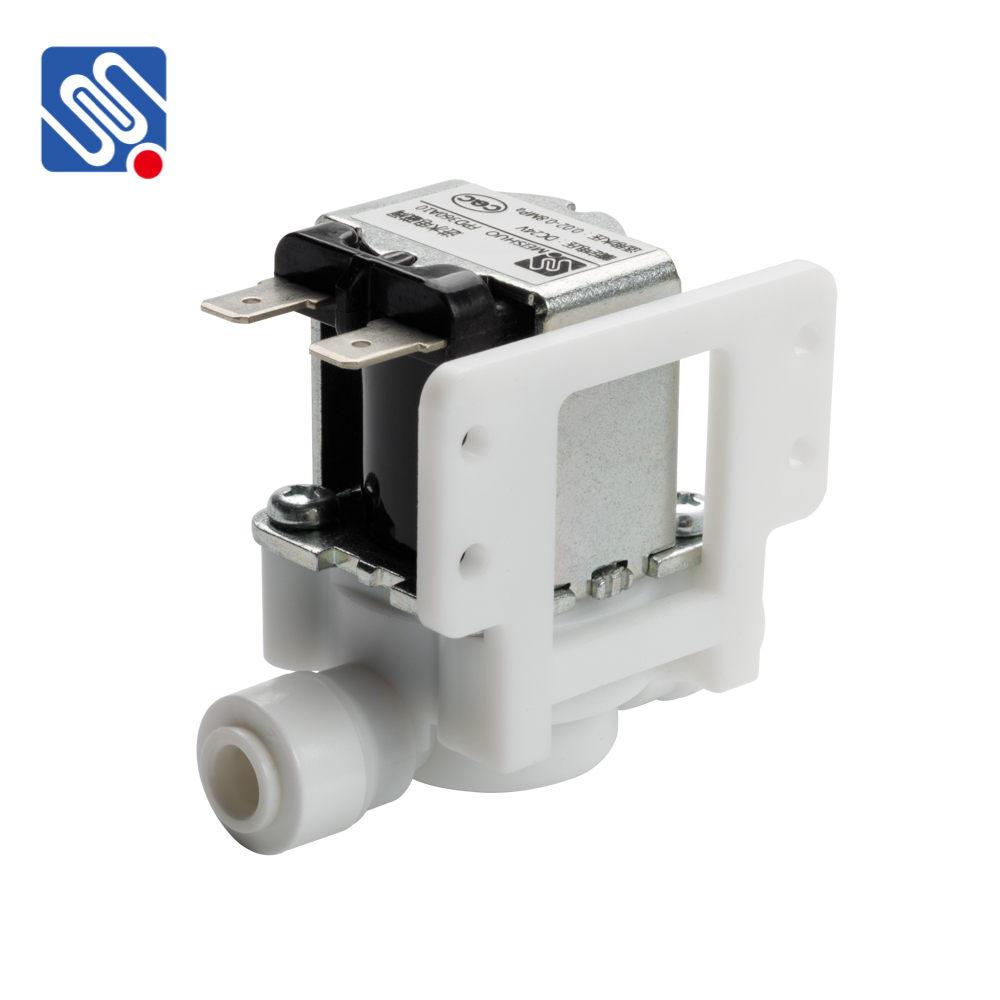

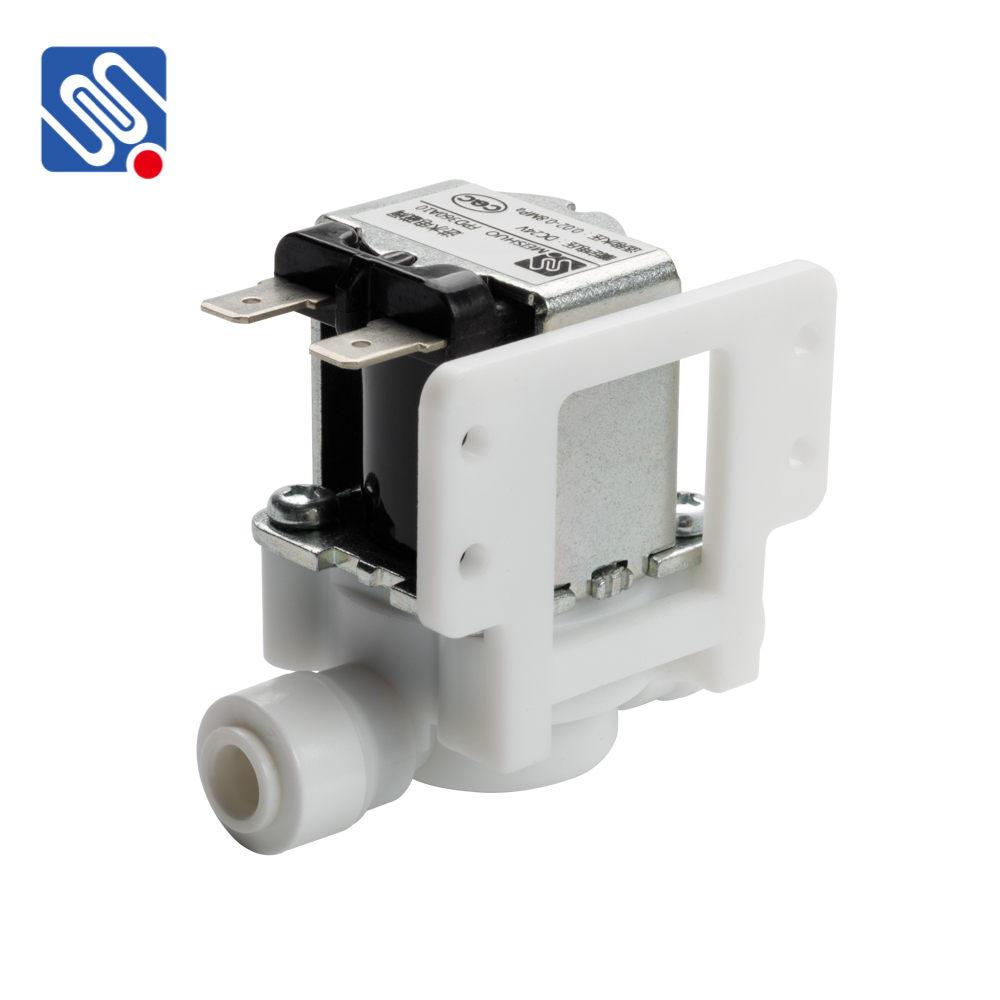

Solenoid valves are essential components in many industries, controlling the flow of liquids or gases through various systems. These valves use an electromagnet to open or close the valve, enabling efficient fluid management. When selecting solenoid valves, one of the most important considerations is the material of the valve body. The two most commonly used materials for solenoid valve bodies are stainless steel and plastic. Each material has its own set of benefits and limitations, and choosing the right one depends on the specific application and environmental conditions. Meishuo, a trusted manufacturer, offers high-quality solenoid valves made from both stainless steel and plastic, catering to a range of industry needs.

Stainless Steel Solenoid Valves

Stainless steel solenoid valves are widely favored in industries where durability, corrosion resistance, and strength are paramount. Stainless steel is an alloy that is resistant to rust, oxidation, and staining, making it an ideal choice for harsh environments. These valves can handle high pressures, extreme temperatures, and aggressive chemicals, making them the go-to option for industries such as oil and gas, chemical processing, and food and beverage production.

One of the standout features of stainless steel solenoid valves is their long-lasting nature. They can withstand mechanical stress and thermal cycles without losing integrity, which reduces the need for frequent replacements. In addition, stainless steel valves are highly hygienic, which is crucial in industries like pharmaceuticals or food production, where contamination risks must be minimized.