Relay production, a cornerstone of modern manufacturing, has evolved significantly over the years, transforming from manual assembly lines to highly automated processes that drive efficiency, precision, and scalability. This article explores the historical development, current practices, and future trends of relay production, highlighting its critical role in various industries.

The origins of relay production can be traced back to the early 20th century with the advent of the assembly line, pioneered by Henry Ford. Initially, relays were manually assembled, with workers performing specific tasks in sequence. However, as demand grew and technology advanced, manufacturers began integrating mechanical and electrical components to streamline production. By the mid-20th century, semi-automated systems emerged, reducing human error and increasing output. Today, relay production leverages cutting-edge technologies such as robotics, artificial intelligence (AI), and the Internet of Things (IoT) to achieve unprecedented levels of efficiency.

Modern relay production processes are characterized by their high degree of automation. Robotic arms, guided by advanced sensors and algorithms, handle intricate tasks like component placement, soldering, and testing with micron-level precision. This not only speeds up production but also ensures consistent quality, as robots can perform repetitive tasks without fatigue or variation. Additionally, IoT-enabled devices collect real-time data from every stage of the production line, allowing manufacturers to monitor performance, detect anomalies, and optimize processes dynamically. For example, predictive maintenance algorithms analyze sensor data to identify potential equipment failures before they occur, minimizing downtime and maximizing productivity.

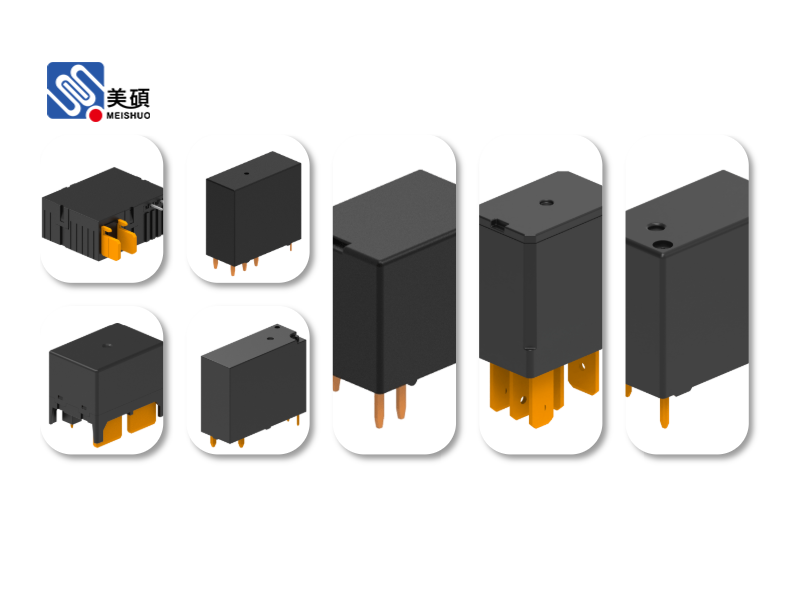

The applications of relay production extend across numerous industries, from automotive and aerospace to consumer electronics and telecommunications. In the automotive sector, relays are essential components in vehicle control systems, power distribution, and safety features. Relay production lines in automotive manufacturing must adhere to strict quality standards, as even minor defects can have severe consequences. Similarly, in the aerospace industry, relays are used in critical systems like flight controls and navigation, requiring production processes that meet rigorous reliability and durability requirements. Consumer electronics, such as smartphones and home appliances, rely on compact, high-performance relays, driving the need for miniaturization and precision in production.

Looking ahead, the future of relay production is poised for further innovation. The integration of AI and machine learning (ML) is set to revolutionize process optimization. AI algorithms can analyze vast amounts of production data to identify inefficiencies, predict demand fluctuations, and adjust production schedules accordingly. Moreover, the rise of additive manufacturing (3D printing) is opening new possibilities for producing complex relay components with reduced material waste and faster prototyping. Collaborative robots, or cobots, are also gaining traction, working alongside human operators to enhance flexibility and adaptability in production lines.

Sustainability is another key trend shaping the future of relay production. Manufacturers are increasingly adopting eco-friendly practices, such as using recycled materials, optimizing energy consumption, and reducing carbon emissions. For instance, some companies are implementing closed-loop systems that recycle waste materials from production processes, minimizing environmental impact. Additionally, the shift towards renewable energy sources, like solar and wind power, for manufacturing facilities is reducing the carbon footprint of relay production.

In conclusion, relay production has come a long way from its manual origins, evolving into a highly automated and data-driven process. Its ability to deliver efficiency, precision, and scalability makes it indispensable in modern manufacturing. As technology continues to advance, relay production will likely embrace AI, IoT, and additive manufacturing, further enhancing its capabilities.同时, a growing focus on sustainability will drive manufacturers to adopt greener practices, ensuring that relay production remains both innovative and environmentally responsible. By staying at the forefront of these trends, the relay production industry will continue to meet the evolving needs of global markets and contribute to the advancement of modern technology.