Relay drive technology plays a crucial role in modern electronics, serving as the bridge between low-power control circuits and high-power loads. This essential component enables microcontrollers and other digital devices to manage heavy-duty electrical systems safely and efficiently. Understanding the fundamentals of relay drive is vital for engineers, hobbyists, and technicians working with automation, robotics, and industrial control systems.

At its core, a relay is an electromechanical switch that uses an electromagnet to open or close a set of contacts. The relay drive circuit provides the necessary current to activate this electromagnet. Unlike solid-state switches, relays offer complete electrical isolation between the control circuit and the load, making them ideal for applications where safety and signal integrity are paramount. This isolation prevents voltage spikes and electrical noise from damaging sensitive control components while allowing the management of high-voltage or high-current devices.

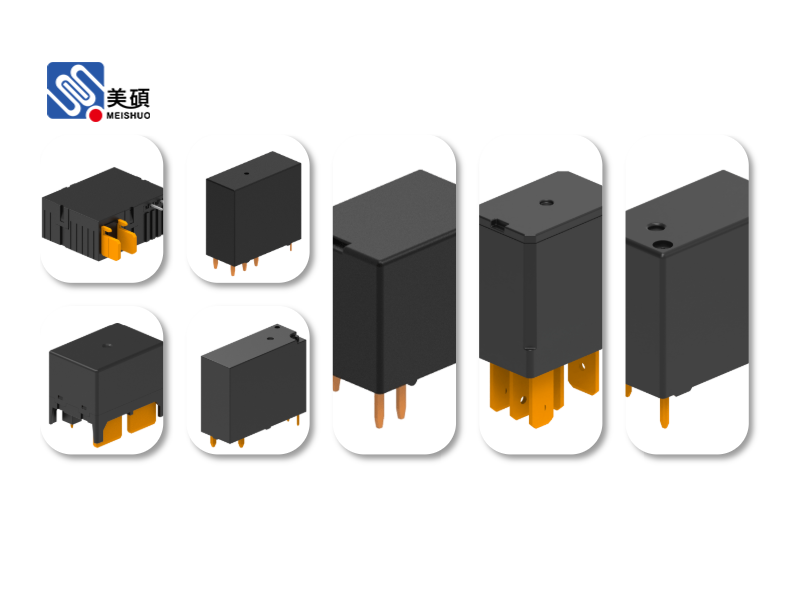

The basic relay drive circuit consists of three main parts: a control signal source (often a microcontroller pin), a switching element (typically a transistor), and the relay coil itself. When the control signal activates the transistor, current flows through the relay coil, generating a magnetic field that pulls the relay contacts closed. This simple configuration can be enhanced with additional components like flyback diodes to protect against voltage transients caused by the collapsing magnetic field when the relay de-energizes.

Selecting the appropriate relay drive components requires careful consideration of several factors. The relay coil voltage and current specifications must match the capabilities of the control circuit. For example, a 12V relay coil might require 50mA of current, which exceeds the output capacity of most microcontroller pins (usually limited to 20-40mA). In such cases, a transistor amplifier stage becomes necessary to boost the current to the required level.

Transistor selection depends on the relay coil current and the voltage rating of the load. Bipolar junction transistors (BJTs) are commonly used for low-power applications, while MOSFETs offer better performance for higher current requirements with lower power dissipation. Darlington pairs or integrated driver chips can provide even greater current amplification for demanding applications.

Relay drive technology finds applications across diverse industries. In automotive systems, relays control headlights, starter motors, and power windows. Industrial automation relies on relays for machine control, process monitoring, and safety interlocks. Home automation systems use relays to manage lighting, heating, and security devices. Even in renewable energy systems, relays play a critical role in connecting solar panels or wind turbines to the power grid.

Advanced relay drive techniques include pulse-width modulation (PWM) control for variable load management and zero-crossing detection for minimizing electrical arcing when switching AC loads. These techniques improve efficiency, extend relay lifespan, and reduce electromagnetic interference. Microcontroller-based relay drives can also incorporate diagnostic features to monitor relay health, detect faults, and provide feedback to the control system.

Designing reliable relay drive circuits requires attention to potential pitfalls. Insufficient coil current may result in intermittent operation or failure to activate the relay. Excessive current can overheat the coil or the driving transistor, leading to premature failure. Proper heat sinking and current limiting resistors help mitigate these issues. Additionally, the physical layout of the circuit affects performance—keeping high-current paths short and separate from control signals reduces electromagnetic interference.

As technology advances, solid-state relays (SSRs) have emerged as alternatives to traditional electromechanical relays. While SSRs offer faster switching speeds and longer lifespans, they lack the complete isolation provided by electromechanical relays and may not be suitable for all applications. Hybrid solutions combining the best features of both technologies are also being developed for specialized use cases.

In conclusion, relay drive technology remains an essential component in modern electronics, offering a reliable and safe method for controlling high-power loads with low-power signals. Its versatility, electrical isolation, and robustness make it indispensable across numerous industries. By understanding the principles of relay operation, selecting appropriate components, and implementing best practices in circuit design, engineers can create efficient and reliable systems that meet the demands of today's technology-driven world. As we continue to push the boundaries of automation and connectivity, relay drive technology will undoubtedly evolve to meet new challenges while retaining its fundamental role in electronic systems.