Relay wiring is a fundamental aspect of electrical engineering and automation, enabling the control of high-power circuits using low-power signals. Understanding the principles and practices of relay wiring is essential for anyone working with electrical systems, from hobbyists to professional engineers.

At its core, a relay is an electromagnetic switch that allows a small current to control a much larger one. The basic components of a relay include an electromagnet, an armature, a set of contacts, and a spring. When current flows through the electromagnet, it generates a magnetic field that pulls the armature, closing the contacts and completing the circuit. When the current stops, the spring returns the armature to its original position, opening the contacts.

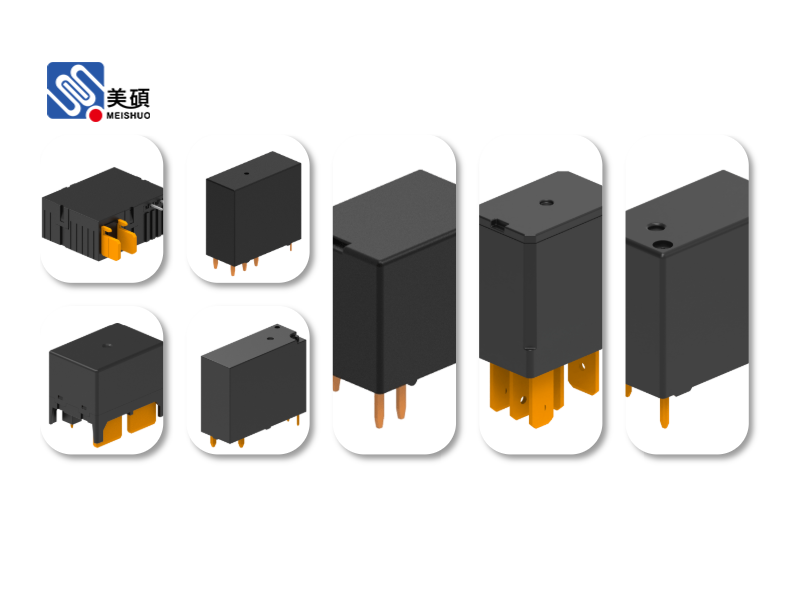

Relay wiring involves connecting these components in a way that ensures reliable operation. The most common configuration is the SPST (Single Pole Single Throw) relay, which has a single set of contacts that either open or close the circuit. Other configurations include SPDT (Single Pole Double Throw), DPDT (Double Pole Double Throw), and latching relays that maintain their state even after the control current is removed.

Proper relay wiring begins with understanding the relay's pin configuration. Most relays have at least five pins: two for the coil (control circuit) and three for the contacts (load circuit). The coil pins are typically labeled with a voltage rating, such as 12V DC or 24V AC, indicating the required control voltage. The contact pins include a common terminal, normally open (NO), and normally closed (NC) terminals.

When designing a relay wiring diagram, it's crucial to consider both the control circuit and the load circuit. The control circuit connects the coil to a power source and a switch, while the load circuit connects the contacts to the device being controlled. It's important to use appropriate wire gauges for both circuits, with larger gauge wires for higher current loads.

Safety is paramount in relay wiring. Always disconnect power before working on any electrical circuit, and use insulated tools to prevent accidental shocks. Overcurrent protection, such as fuses or circuit breakers, should be included in both the control and load circuits to prevent damage from short circuits.

Relay wiring finds applications in numerous industries. In automotive systems, relays control headlights, windshield wipers, and starter motors. In industrial automation, they're used in PLCs (Programmable Logic Controllers) to control motors, pumps, and other machinery. Even in household appliances, relays manage functions like refrigerator compressors and washing machine cycles.

Advanced relay wiring techniques include using diodes to protect sensitive components from voltage spikes, adding indicator lights to show relay status, and implementing time-delay relays for sequential operations. Understanding these techniques allows for more sophisticated and reliable control systems.

Troubleshooting relay wiring issues requires systematic testing. Common problems include loose connections, burned contacts, and coil failures. Using a multimeter to test coil resistance and contact continuity can quickly identify most issues. Regular maintenance, such as cleaning contacts and checking for corrosion, extends the relay's lifespan.

In conclusion, relay wiring is a versatile and essential skill in electrical engineering. By mastering the principles of relay operation, understanding different configurations, and following safety practices, engineers and technicians can design and maintain reliable control systems for a wide range of applications. Whether you're building a simple circuit for a hobby project or designing a complex industrial automation system, proper relay wiring ensures efficient and safe operation.