Relay specifications serve as the technical blueprint for selecting and implementing these critical electrical components across diverse applications. These documents outline the performance capabilities, operational limits, and physical characteristics that define a relay's functionality in circuits ranging from simple control systems to complex industrial automation setups.

The core of relay specifications lies in their electrical ratings, which establish the boundaries of safe and effective operation. Contact ratings represent the maximum voltage and current a relay can switch, with values typically provided for both AC and DC circuits. For instance, a general-purpose relay might specify a 10A @ 250VAC rating for resistive loads, indicating its capacity to handle 10 amperes of alternating current at 250 volts. These values decrease significantly for inductive loads due to the back EMF generated during switching, a critical consideration for motor control applications.

Coil specifications detail the electrical requirements for activating the relay mechanism. Voltage ratings define the minimum and maximum coil voltage, with tolerance ranges often specified to account for power supply variations. Coil resistance, measured in ohms, determines the current draw when energized, influencing power consumption calculations in energy-sensitive designs. The pick-up voltage represents the minimum coil voltage required to close the contacts, while the drop-out voltage indicates when the relay will de-energize and return to its normal state.

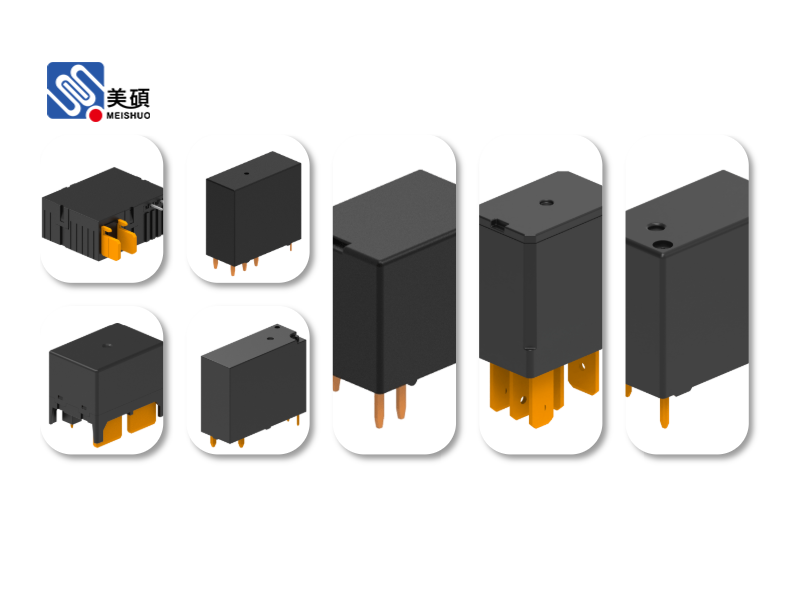

Mechanical specifications address the physical characteristics and operational durability of relays. Contact configuration describes the arrangement of normally open (NO), normally closed (NC), and common (COM) terminals, with standard configurations including SPDT (Single Pole Double Throw) and DPDT (Double Pole Double Throw) designs. Contact material selection directly impacts performance, with silver-nickel alloys offering superior conductivity and resistance to arcing compared to standard silver contacts. Mechanical life ratings quantify the number of switching operations a relay can perform before contact degradation occurs, typically ranging from 100,000 to over 10 million cycles depending on the design.

Environmental specifications define the operating conditions under which a relay maintains its performance. Temperature ranges establish the minimum and maximum ambient temperatures for reliable operation, with industrial-grade relays often specified for -40°C to +85°C environments. Humidity tolerance ratings ensure functionality in moisture-prone applications, while vibration and shock resistance parameters are critical for automotive and aerospace implementations. Protection against dust and liquids is indicated through IP (Ingress Protection) ratings, with higher numbers signifying greater environmental sealing.

Timing specifications characterize the operational response of time-delay relays. These include operate time (the interval from coil energization to contact closure), release time (the period from coil de-energization to contact opening), and adjustable delay ranges for timed models. These parameters are essential for applications requiring precise sequencing of operations, such as motor starting circuits and process control systems.

The importance of understanding relay specifications extends beyond initial selection to encompass long-term reliability and safety. Mismatched specifications can lead to premature failure, circuit damage, or hazardous conditions. For example, exceeding contact voltage ratings may cause insulation breakdown, while insufficient coil voltage can result in intermittent operation. Engineers must carefully match relay specifications to application requirements, considering both nominal operating conditions and potential fault scenarios.

Advancements in relay technology continue to expand specification capabilities, with modern solid-state relays offering enhanced performance in critical parameters like switching speed and lifespan. These innovations require ongoing education to maintain proficiency in specification interpretation. Manufacturers provide detailed datasheets that document these specifications, often including application notes and selection guides to assist engineers in navigating the complex landscape of relay technology.

In conclusion, relay specifications form the foundation of effective component selection and system design. By systematically evaluating electrical ratings, mechanical characteristics, environmental tolerances, and timing parameters, engineers can ensure optimal performance and reliability in their applications. The evolving nature of relay technology underscores the importance of staying current with specification developments, as these documents continue to adapt to meet the demands of increasingly sophisticated electrical systems.