The check valve can check normally under a reverse water pressure of 0.1MPa without any leakage or dripping

Advantage 1: Power saving and water saving: the electromagnetic water valve can be linked and controlled, and the water consumption can be monitored and controlled by the meter, flow meter and0 other equipment, saving water, energy saving and environmental protection.

Advantage 2: High degree of automation: The electric valve uses the motor drive to control the fluid, which can realize the fully automatic operation, the control and adjustment of the electric valve is convenient and fast, and a variety of program control, time control, flow control and other control methods can be realized, and the degree of automation is significantly higher than that of the manual valve.

Advantage 3: Energy saving and environmental protection: The start or stop of the electric valve can be automatically controlled by the controller, effectively avoiding misoperation and energy waste caused by manual operation, thereby further reducing energy consumption and environmental pollution.

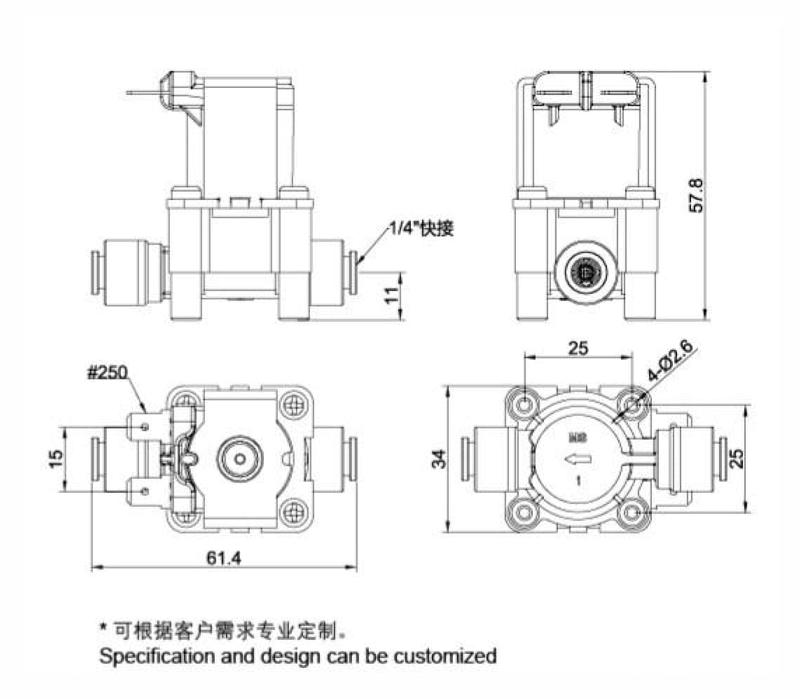

Product Model: | FPD-A2Z |

Rated voltage | DC12V 24V 36V AC110V 220V 50/60Hz |

Pressure Range | 0.02-0.8MPa |

Operate Life | ≥100000 OPS |

Spacing | 25×25mm |

Inlet | 1/4 "quick connect |

Outlet | 1/4 "quick connect |

The FPD-A2Z water inlet solenoid valve is suitable for water purifier control scenarios. It has the advantages of high reliability, fast response, strong durability, easy installation and maintenance, and large flow rate of zero pressure opening valve. The inlet solenoid valve is usually installed before the pressure gauge at the pump outlet. The armature closely fits the inner wall of the pipeline under the action of magnetic field to realize the effective sealing and cut-off of the pipeline. First of all, the appropriate model should be selected according to the actual needs to ensure that the size of its ring mouth matches the installation requirements of the equipment. Then, when installing the water inlet electromagnetic port, choose the right location, away from high temperature, humidity and corrosive environment, to ensure its service life. Ensure the coil tightness during installation to ensure that no accidents will be caused during operation. Pay attention to maintain a suitable working environment temperature during operation, and check and maintain for 3 to 6 months to prevent safety problems. If abnormal conditions are found, stop using the device in time, and check and maintain the device to ensure stable operation.

We offer a one-year product warranty. If any issues arise within this period due to product defects, we will provide free replacements or refunds.

We can customize the packaging according to your needs.